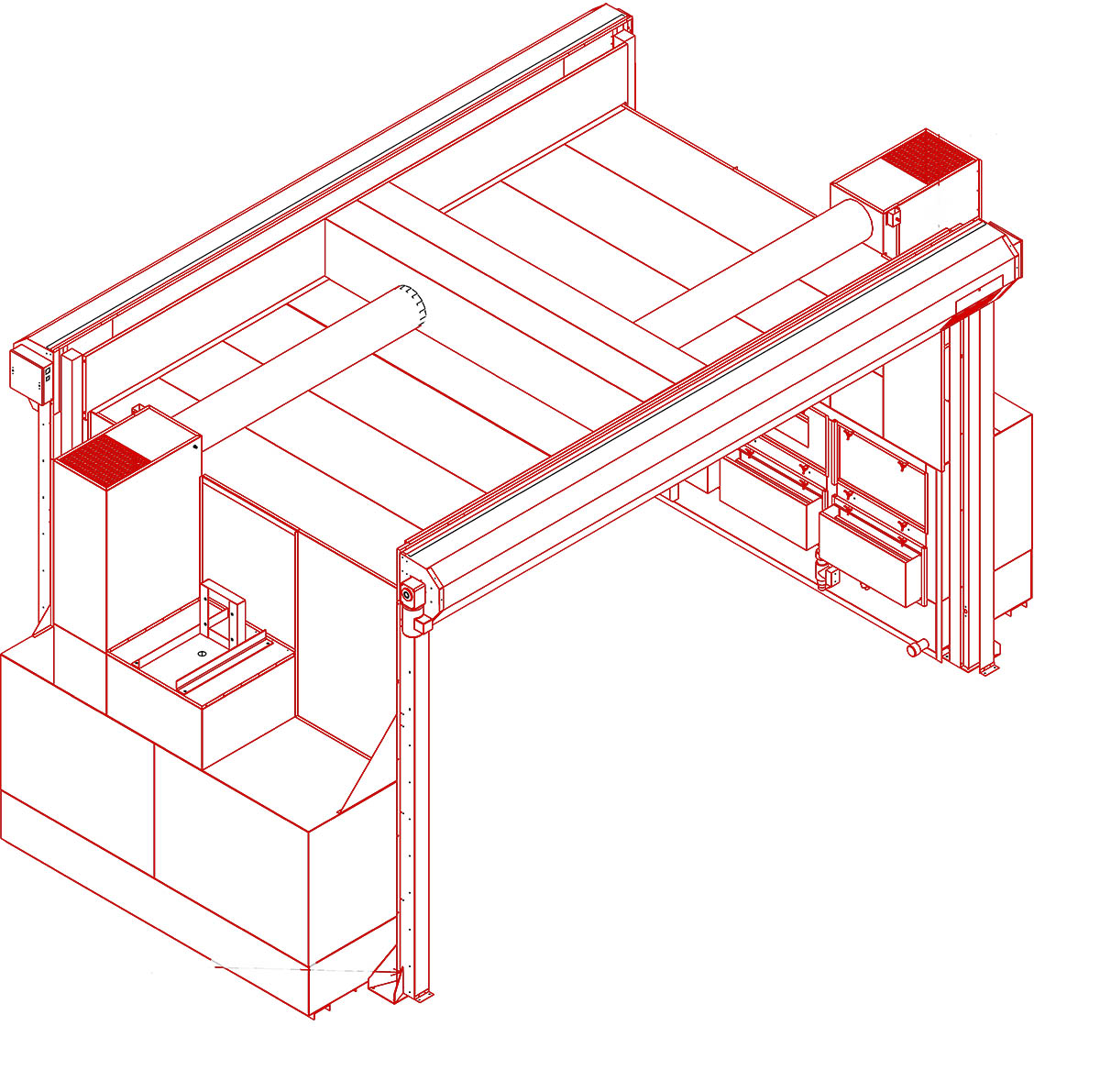

Industrial Finishing

DESIGNED FOR Environmental separation APPLICATIONS

By far the fastest growing member of the RollSeal line of custom door solutions, our Industrial Finishing Door Systems are creating waves in the industry and revolutionizing the way doors are viewed in the paint and powder coating markets.

Environmental separation applications have always been RollSeal’s claim to fame, but the air-tight sealing system, automated operation and small footprint combined with the ability to stand up to the harsh environments that can be present in the industrial finishing market has been what truly sets the RollSeal Door apart from conventional style rigid doors that have been historically used in these markets.

Environmental separation applications have always been RollSeal’s claim to fame, but the air-tight sealing system, automated operation and small footprint combined with the ability to stand up to the harsh environments that can be present in the industrial finishing market has been what truly sets the RollSeal Door apart from conventional style rigid doors that have been historically used in these markets.

If you are looking to create a more energy efficient operation with increased productivity, faster product turns, no cool down cycles and less down-times; while at the same time providing a safer work environment for your associates, then you need to look into retro-fitting to a RollSeal Industrial Finishing Door solution.

We can custom design a door to meet your specific needs from wet paint (Class 1 Div 1, Class 1 Div 2) booths all the way up to 500°F oven applications.

Industrial Finishing Applications:

• 200F & <

• Wet Paint

• Dry Paint

• 500F & <

• Small Batch

• Up to 16’x16’ Openings

• Clean Rooms

• Paint Mix

• Manufacturing

• High Humidity

• 200F & <

• Chemical Resistant Panel

• Stainless Steel Options

• Chemical Resistant Panel

• Small Footprint

• Multiple Panel Configurations

• Single Layer Partition

ROLLSEAL FEATURES:

• Patented Technology

• Impact Resistant

• Reduces Operational Footprint

• New Construction or Retro-Fit

ROLLSEAL TECHNOLOGIES:

• 3-Layers of Fabric Creating Space

Between Environments.

• Continuous Seals on Both Sides of Door, Front and Back Panels.

CUSTOM SIZES AVAILABLE:

Custom Sizes

Custom sizes up to 24′ x 24′

Custom Speeds

Custom speeds up to 48” per second

EASY SETUP & INSTALL:

STEP 1 – Placement

STEP 2 – Stand Up & Mount

STEP 3 – Electrical

Ready to Use!

INDUSTRIAL FINISHING

RollSeal™ Doors are the perfect fit for a number of companies and environments in the industrial finish industry. Our sealing technology creates an airtight environment for your product, and our small footprint can easily adapt to areas with space limitations.

Powder Coating Oven/Cure

Designed with EISA regulated applications in mind, Operational temperature ranges up to 500° F.

Environmental Rooms

Air-tight seals eliminate cross contamination between operational environments.

Spray Booths Wet/Dry

Explosion proof operator options available for hazardous environments.

Battery

Curing

Doors designed to withstand high humidity and moisture, 200°F temperatures and 100% humidity.

Industrial Wash/Clean

Corrosion resistant panels, all stainless steel to withstand moisture, humidity and chemicals.

Over the years, RollSeal has developed a diverse line of products that utilize our patented sealing technology. These products have ranged from roll-up fabric doors, to roll-up shutters to rolling sidewall systems. We specialize in making custom solutions that meet the needs of a wide range of markets and applications and would love to be a part of the design phase of your next project.