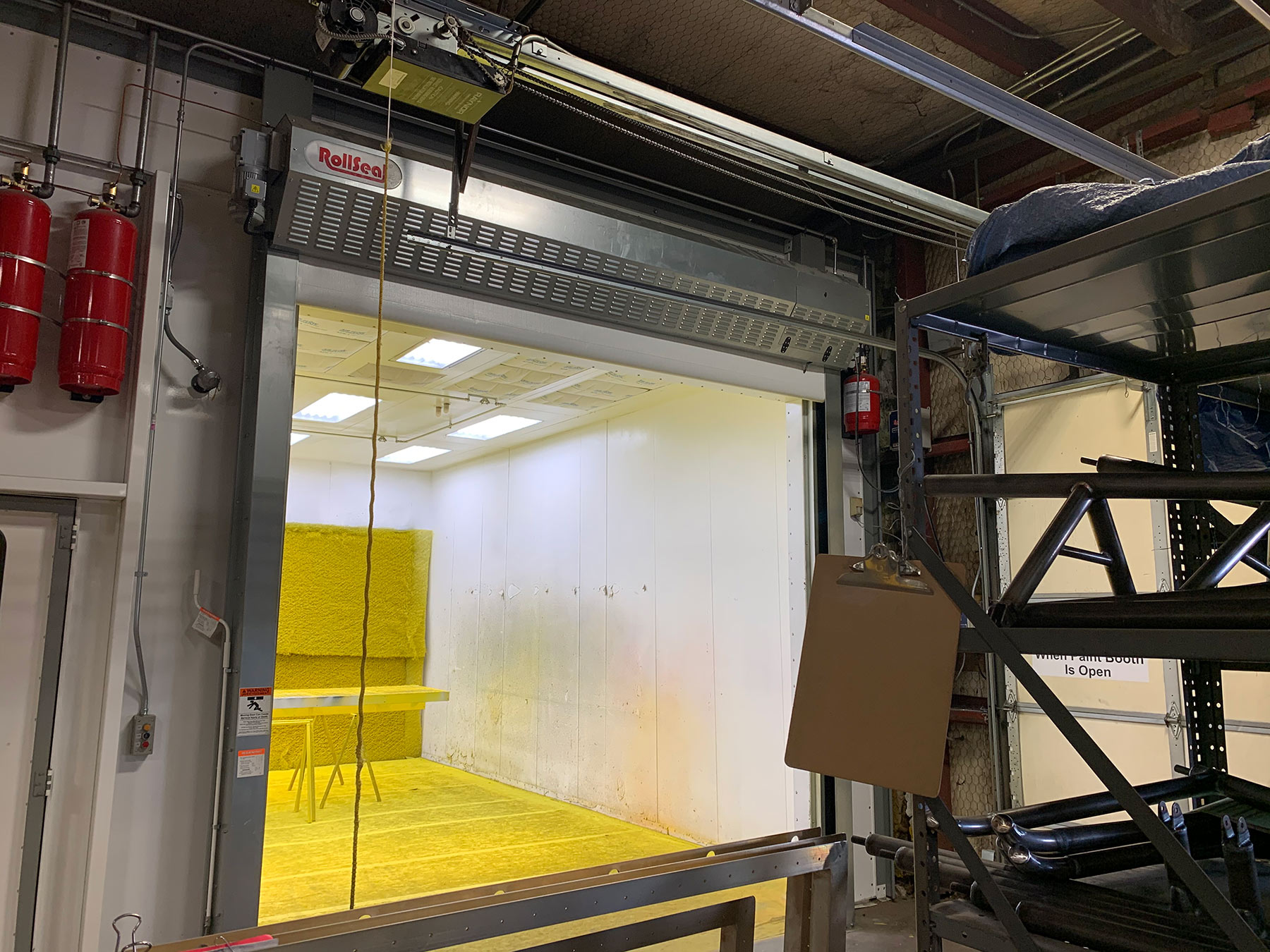

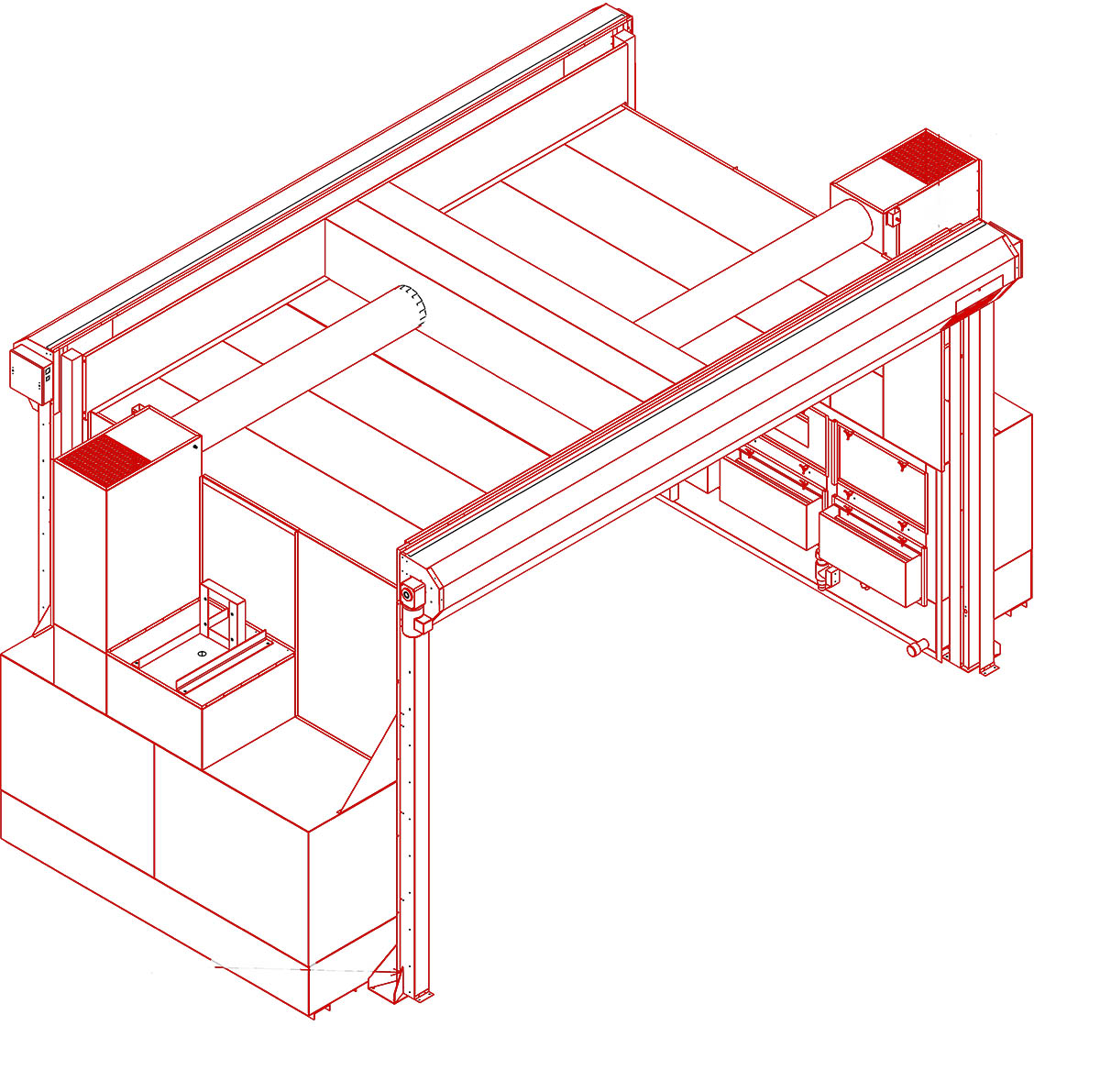

Paint Booth Doors

IDEAL SOLUTION FOR CREATING SEPARATION BETWEEN ENVIRONMENTS!

Sizes up to 24’ wide and 24’ tall

Speeds up to 36-48” per second

115v/230v Single Phase 50/60Hz

ROLLSEAL MANUALS, CUTS SHEETS & INSTRUCTIONS

–4801-9003 (RS-500M, RS-600M Intrinsically Safe Barrier Door Manual)

–4802-7549 (RS-600 Paint Booth Door Cut Sheet)

–4802-7572 (Relay Output Termination)

–Industrial Paint and Finishing Tri-Fold Brochure

ROLLSEAL DOOR FEATURES INCLUDE:

• Patented, Air-Tight Sealing Technology

• Impact Resistant Design

• Variable Speed up to 48”/Second

• Ideal for New Construction or Retro-Fit Applications

• Reduction in Operational Footprint

• Quick Installation Time

• Custom Sizes Available

• PLC Communication Capabilities to Monitor Door Location

Temperatures: (200°F & < Applications)

Designing a door that can stand up to the harsh environment and daily challenges faced in wet paint booth applications is a challenge for any door company. So, when RollSeal began researching whether our solution(s) would be a good fit for paint booth applications, we did our research and worked with the leading paint booth manufacturers in the world to assure that we could provide a solution that was at the same time innovative, affordable and user-friendly.

It all starts with the unique, patented sealing system design. The RollSeal Door’s triple layer fabric and air-tight seal prevent overspray from escaping the paint booth and keeps contaminants out of your paint jobs and its “floating” seal design allows the door to maintain a complete, continuous seal under high variations in static pressure.

It all starts with the unique, patented sealing system design. The RollSeal Door’s triple layer fabric and air-tight seal prevent overspray from escaping the paint booth and keeps contaminants out of your paint jobs and its “floating” seal design allows the door to maintain a complete, continuous seal under high variations in static pressure.

Class 1 Div 1 explosion proof

options available

Paint Booth Door: Overview

The RollSeal Door also comes with a variable speed operator that can be easily adjusted, keeping air and dust out of the paint booth at the most critical times. Additionally, all of the doors are certified to be intrinsically safe and are available in versions that can be installed in hazardous/explosion proof environments.

All of these design features that are specific to the RollSeal Paint Booth Door are combined with the standard features such as small footprint and quick and simple installation/set-up to create a door that will immediately shift your operation to be more efficient, safe and productive.

Paint Booth Door: Safety Features

Paint Booth Door: Basic Troubleshooting

Powder Coating Oven/Cure

Specialized fabric designed for oven applications capable of withstanding operational temperature ranges of up to 500F

Environmental Rooms

Air-tight seals eliminate cross contamination between operational environments.

Spray Booths Wet/Dry

Explosion proof operator options available for hazardous environments.

Battery

Curing

Doors designed to withstand high humidity and moisture, 200°F temperatures and 100% humidity.

Industrial Wash/Clean

Corrosion resistant panels, all stainless steel to withstand moisture, humidity and chemicals.