As the door closes, the drive pipe rotates, spooling 3 layers of fabric down into place with the interior of its protective tracks; positively sealing with industrial grade magnet or commercial hook-and-loop. The front, middle and rear panels are seamed together forming 2 pockets. This design allows for each tension pipe to be encompassed independently in the front and rear panels. The sealing process is made possible by these 2 tension pipes.

The tension pipes utilize gravity to lead the panel down and apply pressure to the front and rear panels. This presses them against the vertical door tracks, ensuring that the proper seal is made. When the door reaches the floor, a continuous seal has been formed around the perimeter of the door for both the front and rear panels. An air space is created between the layers of fabric, further separating your environments. When opened, the drive pipe rotates. This brings the panel up as it is wound onto the drive pipe. In the open position, the tension pipes disunite the seal between the panels and another material … a fabric known as “floating” … by separating the two materials as they roll up.

In this sealing category, the hook (male) is sewn to the front and back door panels. When the panel rolls down, it is mated to the loop (female) material. The loop material is sewn to the material known as “floating” and is attached within the track system.

Applications for use of hook-and-loop sealing systems include Ripening Room Doors, Paint Booth Doors, Oven Doors, Battery Curing Chamber Doors, E-Room Doors, or any exterior mount or high static pressure/wind load door.

In this sealing category, industrial grade spring steel is attached to the front and back door panel. When the panel rolls down, it is mated to high intensity magnets.

The magnet materials are attached to the material known as “floating” that is attached within the track system. Applications for use of magnetic sealing systems include all refrigerated and cold storage doors.

Touch Free Technologies

Among other standard features (variable-speed controls, automatic closure, movement warning lights, etc.) RollSeal doors can adapt accessories to make operation completely touch-free.

Among other standard features (variable-speed controls, automatic closure, movement warning lights, etc.) RollSeal doors can adapt accessories to make operation completely touch-free.

Touchless Activation Kits include a combination of Passive Infrared Motion and/or Wave Sensors that enable your door to be activated without touching a conventional switch. This optimizes the flow of traffic throughout your facility; for example, personnel do not have to press a button to open the door. Furthermore, whether in a food processing facility or a manufacturing plant, touchless activation reduces the spread of pathogens as personnel do not have to make physical contact with the communal activation switch.

The sensors can be mounted in various ways (either on or near the door) to suit your particular application.

VIDEO: RollSeal Built-In Motion Sensor

The built-in motion sensor allows the door to be activated without pushing a button. The small integrated sensor is calibrated so that it is only activated in close proximity to the door … eliminating nuisance triggers. This feature can be used as activation or as a secondary safety feature.

Passive Infrared Sensor

Wave Close-Proximity Sensor

Smart Controller

As a company that has manufactured complex electronic control systems since the late 1980’s, we have controller units installed in applications ranging from agriculture to high-end industrial all over the world. All refrigeration application model RollSeal Doors come complete with a custom designed “SMART” Controller unit that serves as the brain-box of the door. Simple to use interface and flashing LED technology make the controller both complex and user-friendly at the same time. You can simply adjust settings of the door such as speed and close-time delay. Additionally, the controller keeps up with historical cycle count data for the door and flashes a custom code anytime something is wrong to make troubleshooting a breeze. We also have a 24/7 technical support line and are more than willing to walk you through any question at any time day or night.

As a company that has manufactured complex electronic control systems since the late 1980’s, we have controller units installed in applications ranging from agriculture to high-end industrial all over the world. All refrigeration application model RollSeal Doors come complete with a custom designed “SMART” Controller unit that serves as the brain-box of the door. Simple to use interface and flashing LED technology make the controller both complex and user-friendly at the same time. You can simply adjust settings of the door such as speed and close-time delay. Additionally, the controller keeps up with historical cycle count data for the door and flashes a custom code anytime something is wrong to make troubleshooting a breeze. We also have a 24/7 technical support line and are more than willing to walk you through any question at any time day or night.

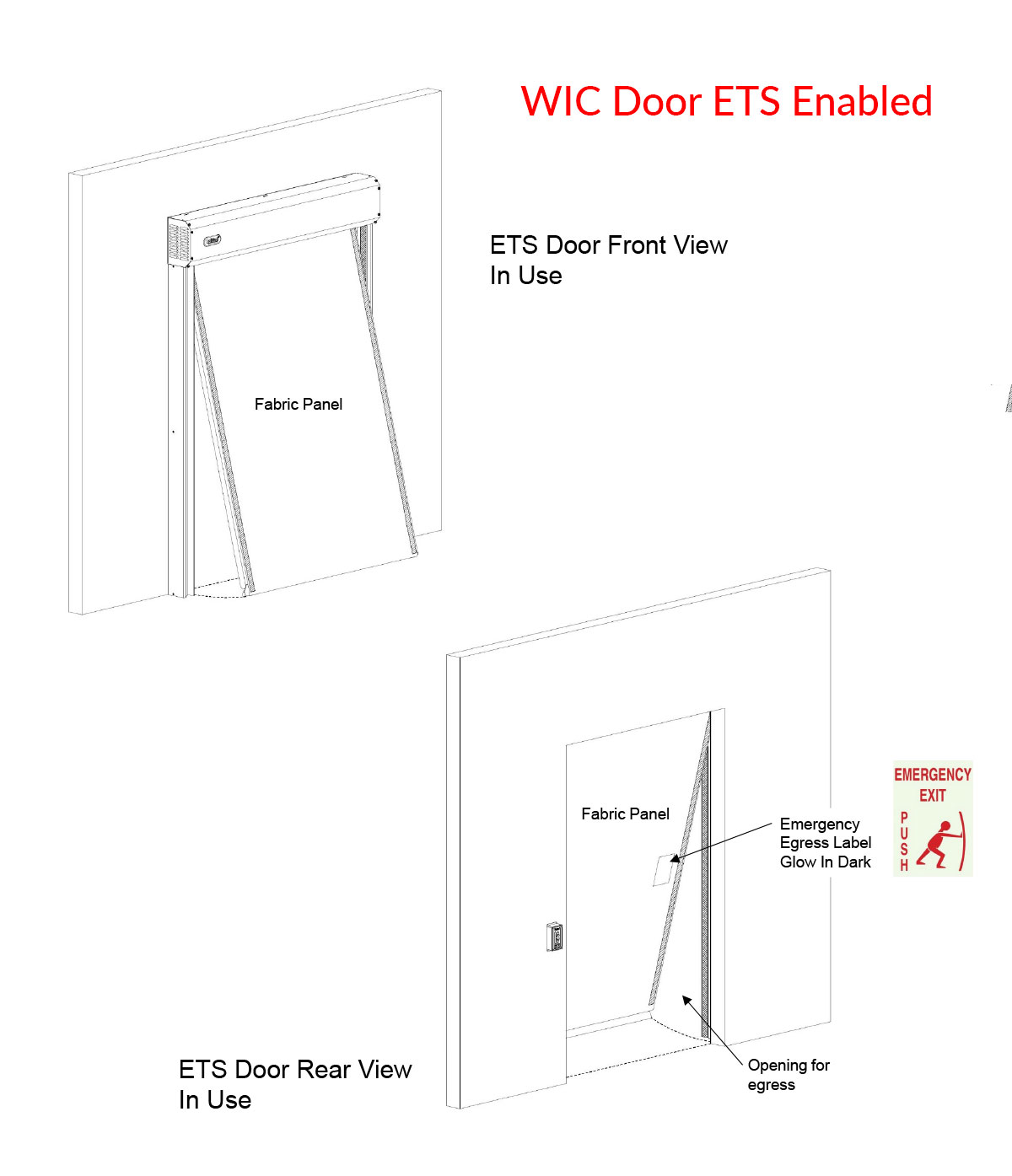

Emergency Egress Systems

In many applications, code requires the RollSeal Door to provide emergency egress so that the door can be exited in the event of a power failure. The RollSeal Door offers two methods of egress for our various door models, the ETS (Egress Track System) and the ESS (Egress Strap System). The ETS is integrated into the WIC model cooler door as well as several of the Night Door models that we manufacture. This egress system allows the door tracks to swing open when the fabric panel is pushed from the inside of the door. The ESS is an optional feature on RS500 and RS600 door models up to 10’ in height. This method of emergency egress utilizes a pull strap located in the top center of the inside of the door that can be pulled to raise the door in the event of a power failure. Additionally, any RollSeal Door can be lifted up by hand to create an exit in the event of emergency … after all, it is a fabric door.

In many applications, code requires the RollSeal Door to provide emergency egress so that the door can be exited in the event of a power failure. The RollSeal Door offers two methods of egress for our various door models, the ETS (Egress Track System) and the ESS (Egress Strap System). The ETS is integrated into the WIC model cooler door as well as several of the Night Door models that we manufacture. This egress system allows the door tracks to swing open when the fabric panel is pushed from the inside of the door. The ESS is an optional feature on RS500 and RS600 door models up to 10’ in height. This method of emergency egress utilizes a pull strap located in the top center of the inside of the door that can be pulled to raise the door in the event of a power failure. Additionally, any RollSeal Door can be lifted up by hand to create an exit in the event of emergency … after all, it is a fabric door.

Tension Pipes

Every model of the RollSeal Door comes standard with two tension pipes situated in the pockets formed by our 3-layers of fabric and our patented floating seal system. These tension pipes come in 3 different material options and change depending on the application of the door. The Foam/Fiberglass option comes standard in many refrigerated and traffic doors. These tension pipes are rigid enough to keep the door functioning properly, while being flexible enough to avoid being damaged by an impact. Our Standard Metal option is a universal pipe that can be used in all of our doors. Most industrial finishing applications, especially in high heat applications, will use this type of tension pipe. The Standard Metal pipes are a rigid design that can span widths of 24’. Lastly, the Impact Resistant Metal pipes are similar to the Standard Metal, but they have the addition of two knuckles or joints that allow these pipes to give way if impacted. The Impact Resistant Metal pipes can be used in many of the applications that the Foam/Fiberglass and Standard Metal are utilized and can stand up to frequent impacts, but are mainly used in industrial finishing applications where the door has to be rated for explosion relief.

Every model of the RollSeal Door comes standard with two tension pipes situated in the pockets formed by our 3-layers of fabric and our patented floating seal system. These tension pipes come in 3 different material options and change depending on the application of the door. The Foam/Fiberglass option comes standard in many refrigerated and traffic doors. These tension pipes are rigid enough to keep the door functioning properly, while being flexible enough to avoid being damaged by an impact. Our Standard Metal option is a universal pipe that can be used in all of our doors. Most industrial finishing applications, especially in high heat applications, will use this type of tension pipe. The Standard Metal pipes are a rigid design that can span widths of 24’. Lastly, the Impact Resistant Metal pipes are similar to the Standard Metal, but they have the addition of two knuckles or joints that allow these pipes to give way if impacted. The Impact Resistant Metal pipes can be used in many of the applications that the Foam/Fiberglass and Standard Metal are utilized and can stand up to frequent impacts, but are mainly used in industrial finishing applications where the door has to be rated for explosion relief.

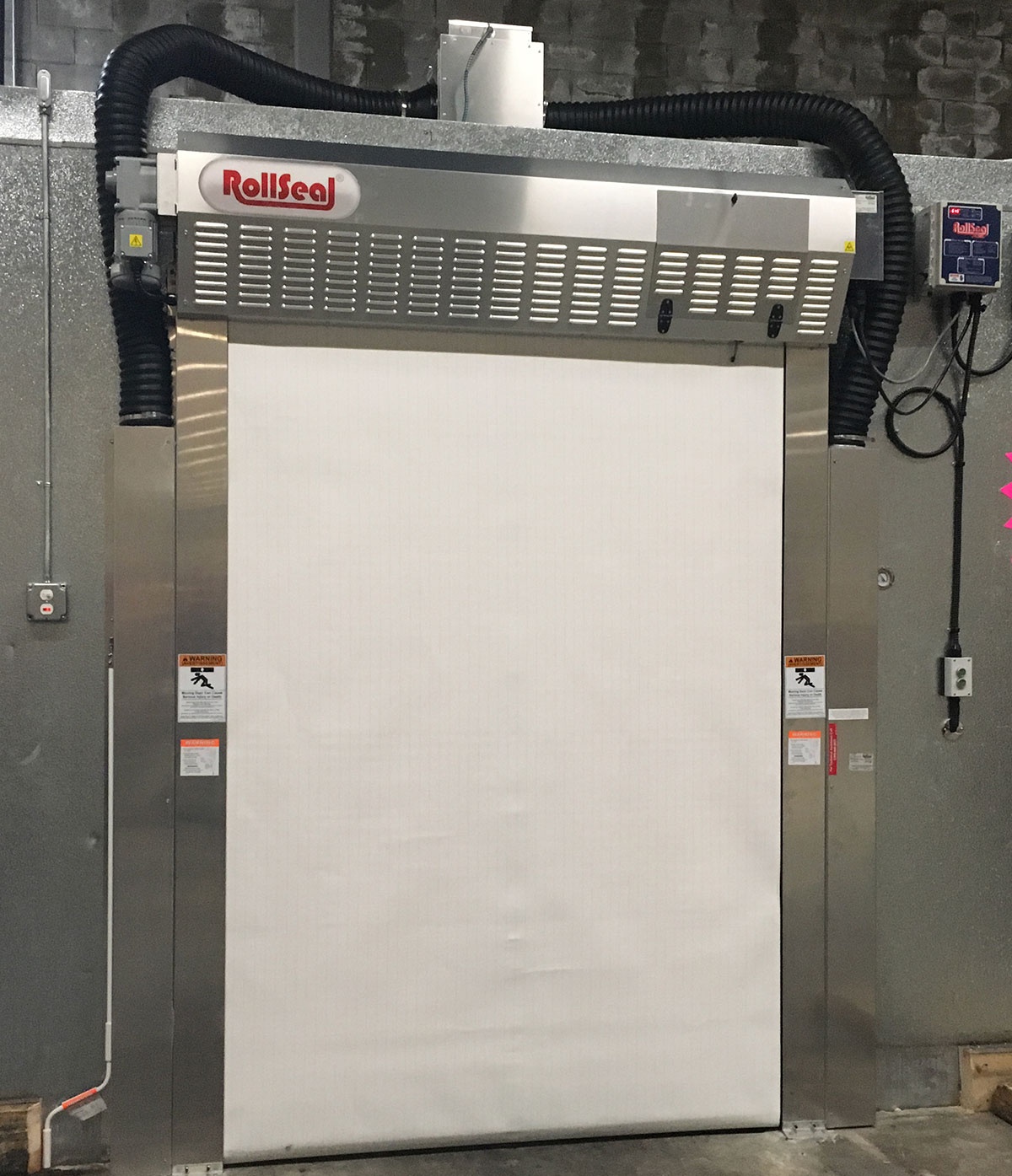

Condensation Management Systems

In refrigerated applications, the RollSeal Door can also come complete with our CMS (Condensation Management System). We use this system standard on all freezer door models, but also can have it as an add-on component for cooler doors that are installed in areas with a very high temperature delta from one side of the door to the other. The 3-layer design of the RollSeal Door creates a dead air space between the front and back fabric panels. With the CMS, we utilize this air space to recirculate heated air throughout the fabric panels in order to control the temperature and humidity of the door. The CMS contains a heating element and a blower to move the heated air. The unit connects to the door tracks (legs) through field adjustable flex-hoses on each side of the door, which act as heavy duty duct work to distribute the heated air evenly across the surface area of the fabric panels. The air travels throughout the interior of the door fabric, fighting off the formation of condensation both on the exterior and interior of the door.

In refrigerated applications, the RollSeal Door can also come complete with our CMS (Condensation Management System). We use this system standard on all freezer door models, but also can have it as an add-on component for cooler doors that are installed in areas with a very high temperature delta from one side of the door to the other. The 3-layer design of the RollSeal Door creates a dead air space between the front and back fabric panels. With the CMS, we utilize this air space to recirculate heated air throughout the fabric panels in order to control the temperature and humidity of the door. The CMS contains a heating element and a blower to move the heated air. The unit connects to the door tracks (legs) through field adjustable flex-hoses on each side of the door, which act as heavy duty duct work to distribute the heated air evenly across the surface area of the fabric panels. The air travels throughout the interior of the door fabric, fighting off the formation of condensation both on the exterior and interior of the door.